Glass 101 – Different types of glass

What is glass and how is it made?

Glass as a material is solid-like and transparent. In simple terms, it is made from naturally occurring raw abundant materials, namely sand, soda ash, and limestone. They are melted at a very high temperature, and they create glass. There are different methods for creating different types, such as pyrex, soda, or flint. If you want to read more, there is an amazing, more technical explanation here and here.

Basic glass

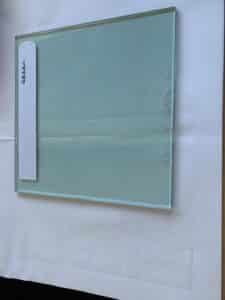

This refers to any glass that has not been tempered. Other names associated with the basic types of glass are annealed, or float. It is created by rapidly cooling down the heated glass. There are no other modifications done, and it is glass in its purest form. Pretty, but fragile. When it breaks, it shatters, and it can cause injuries, such as cuts.

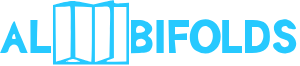

Did you know: Float glass is made by floating molten glass on a bed of molten metal, typically tin. Sometimes it’s also known as the Pilkington Process.

Toughened / Strengthened glass

Annealed glass that has been thermally or chemically treated to modify its strength is called toughened or strengthened. It is a safer option than the basic one, but not as secure as laminated.

Toughened glass has a higher thermal and physical strength compared to annealed, but it can easily break. When it breaks, it shatters into small pieces. The advantage of toughened glass is that when it shatters into small pieces, the pieces are blunt, therefore you much less likely get injuries such as cuts on your body. Pieces are more or less harmless to your skin, making toughened a safer option than the basic one. The reason for this is simple. The shards have no sharp edges.

The downside of toughened glass is that even though it is structurally strong, its edges are not. If you insert a sharp object into the edge of the frame, it shatters quickly. It is more affordable compared to laminated, but also a bit less secure.

Did you know: If your windows or bifolds are lower than 800mm from the floor level, safety glass (either toughened or laminated) has to be used.

Laminated glass

Annealed, toughened, heat-soaked, or heat strengthened glass (in any combination) with an inter-layer is called laminated. It usually consists of two panes that are held together by an inter-layer. If you’d like to know more, here is a quick post.

Laminated glass is considered one of the safest options available, as it is not only strong and sturdy, but durable as well. As there are two panes and an inter-layer, breaking it is very difficult. When it comes to small impacts, most likely nothing will happen. And if by any chance laminated glass breaks, it only breaks on one side. There will be a small hole and a spider web-like pattern. The inter-layer will hold panes together, making it a safe and secure option.

Living in more dangerous areas, or areas more affected by severe weather conditions, laminated type is your go-to option. If something happens, let’s say an earthquake, the inter-layer will hold panes together, so they will not shatter everywhere, leaving you a safe route to escape.

Compared to toughened ones, laminated is more expensive, but it provides more safety and security. It also provides more noise reduction and more UV resistance.

Coated glass

Any of the above-mentioned glass types can also be coated in order to give it different properties. This can be a coating within the glass or applied to its surface. One of example is mirror coating, which you can often see in commercial buildings. Its main purpose is to block harmful UV rays while also shielding the inside of the building from prying eyes! You can see there is a window, but you cannot see through it.

Another type of coating which is good for conservatories, south-facing windows or roof lanterns/ roof lights is a type of solar glazing. We use Cool-Lite SKN 176 which has a special neutral appearance. It lets in 70% of light while reflecting up to 63% of external heat compared to standard glass, which can sometimes only reject 27% of the Sun’s heat. The excellent thermal insulation also reduces heat loss from inside the room in cooler months making it a solid all-around upgrade to your glazing.

This “solar” glazing is also sought after by people who either have expensive art at home and want to protect it or have valuable photos and prints on the walls facing the window. The coating protects the art from harmful UV Sun rays coming through the window reducing fading and damage.

Keep in mind that coating and colouring are not the same. There are also different colours of glazing to choose from, usually bronze, green, and blue tints. These can also vary slightly depending on the company manufacturing the tinted glass. Having coloured windows is also not only an aesthetic choice, some colours offer different UV protection, and they can also help with heat retention in the winter and reflecting heat away in the

summer. Coloured glass can give your property character and is often a design choice.

Another option, if privacy is a concern, is to choose glazing that has an “obscure” finish. When we talk about obscure glass many people think of the older styles of having flowers or leaves on the glass; think of your old bathroom windows! We still have many designs, and each design offers a different level of privacy. Levels go from 1 – 5 depending on the design. A popular choice in more contemporary homes is to have frosted satin

obscure or sandblasted. These give an optimal level 5 privacy where you can only really see fuzzy shapes and vague shapes and is also sleek and modern looking while still letting in loads of light.

How can I tell the difference?

When it comes to basic (annealed), toughened, and laminated, the thing gets trickier. The easiest, though not the most practical way how to tell the difference is to break it.

- Basic breaks into sharp, dangerous pieces

- Toughened shatters into small, but blunt pieces

- Laminated does not shatter, there will be a spider web-like pattern instead, and inter-layer will hold it together

If you want to learn how to tell the difference between those types without breaking it and causing potential (physical and monetary) damage, there is a small guide.

If you have watched Squid Games, you can recall one of the “games” where the contestants have to walk through a bridge, and the steps were made from glass. One contestant was able to see and hear the difference between tempered and regular one.

So, does that mean you can see or hear the difference and spot which type it is?

Technically, and theoretically, yes. It is not easy, though. To the naked eye, they all may seem the same at the first glance. When you look closely, the edges of the regular one are sharper, while the tempered ones are more round and smooth. This may not help a lot when you’re looking at a window, though, as you cannot see the edges.

When you temper the glass, it goes through a lot, which can show on its surface. If there are any imperfections, bends, or curvatures, you are looking at something that has been tampered with.

“If you look at the tempered glass from an angle under the light, you can see faint stain marks.”

Squid Games

The next question is, how can you tell the difference between toughened and laminated? This is where things are getting tricky. Although there is an inter-layer added during the lamination process, you cannot spot it. The only difference would be the thickness. And even then, you need to have a very good and trained eye to tell the difference between 4mm and 6.4mm

Otherwise, looking at a window and trying to figure out by sight if it’s laminated or toughened is impossible. With double and triple glazing being the standards, looking at the thickness of a window from the side will not help you at all. However, most of the panes nowadays have a small mark in the corner saying which type it is.

In conclusion, you can easily spot the difference between coated and non-coated glass. You can also spot the difference (although not as easily as before) between regular and tempered ones. But you cannot spot the difference when it comes to toughened and laminated. Unless you have spent your whole life working with glass knowing every little detail, you can only guess.

Here, at AL Bifolds, we use toughened A-rated (low E) as a standard, unless requested otherwise. If you have any further questions, feel free to get in touch on any of the following: Facebook, Instagram, Twitter, LinkedIn.

We use toughened glass as standard, because we take safety and security of our products very seriously. It is the best option if you want safe and sturdy, but still affordable bifolds doors or windows. With business, especially shops, combination of laminated and toughened is used for extra security, so when someone breaks the shop window, laminated glass on the outside will hold it together. If there is a strong impact and inside glass shatters, it will not hurt customers and staff, as it breaks into those small, blunt pieces mentioned earlier.

With households, we always offer a choice between toughened and laminated. We do not really like basic (float, annealed, etc.) option, unless specifically asked. It may be the cheapest option, but it is not as safe and secure as other ones, and it is not as energy efficient either. In the long run, toughened glass is the best option, unless you want the extra benefits that lamination offers.

Where is each type used?

Taking a guess and being correct is easier when you know where each type is being used. In the table below you can see the general usage, but more and more businesses (and house owners) are swapping toughened and laminated glass around quite a lot. It is very interchangeable nowadays. In most cases, shops are opting out for extra security, and have toughened glass inside and laminated outside.

| Basic | Older windows |

| Toughened | Shower doors; Microwave plates; Fridge plates; Modern Windows, Bifolds, Sliders |

| Laminated | Car’s Windshield; Shop windows |

| Coated | Museums; Art Galleries |

Fun facts about glass

It can be naturally formed by lightning hitting the sand!

It can be recycled over and over again, as it is 100% recyclable!

Colour is not created by adding dies, it is created by adding different minerals!

It is not classified as solid, liquid, or gas. It is an amorphous solid!

It can be dissolved with hydrofluoric acid!